We do machine processing and assembly of precision sheet metal parts primarily and its associated parts.

We deliver high quality products to you in two days at an average.

Product Name: Medical Device Case

| Processing Method |

Bending, Assembling, Electro Deposition |

| Material |

SPCC |

| Thickness |

t = 1.2mm |

| Dimensions |

270mm×185mm×160mm |

| Required Lots |

50 |

| Utility |

Medical Device (Light Source of Gastroscope etc.) |

| Required time |

10 days |

| Group |

Mass Production |

| Request |

Fabricate up to assembly of electrical parts |

| Description of Product |

|

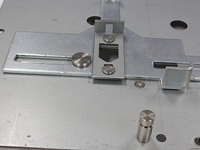

We undertake assembly of electrical parts. Press fitting of nuts is also workable.

|

Processing Features

Assembling

|

We, CREST PRECISION, provide welding, bending, and also assembling, for the special benefits of reducing the workload on the customer’s side.

|

Electro Deposition/ Coating

|

The subcontract factory of CREST PRECISION has undertaken electro deposition, various coatings and plating. We ensure that we can accommodate and offer your need of surface treatment.

|

Blanking

|

CREST PRECISION has adopted NC Turret Punching and Laser Punching for blanking.

We can handle various types of precision sheet metal parts and products due to our capabilities in handing very complex blanking.

|

Bending

|

CREST PRECISION processing technology with our skilled and accurate work ensures the production of parts to meet your required specifications. We never fail to check up after the bending. Those our diligent work results in high quality products.

We are equipped with a range of bending equipment - from 25t to 130t to be responsive to requests in bending various sizes and bending rate.

Long parts, over 2,000mm in length, are worked to realize a unified angle and R (rate) at every bending point.

|